![]() Engineers are obsessed with making everything on their own with an attitude of “I can do it” which is good but the market do not care about that. Whatever product you are making, it is very important to understand that it will be successful only if it solves a problem, launched timely to the market, easy to use, customers are happy with the experience, and quickly adapts to future requirements.

Engineers are obsessed with making everything on their own with an attitude of “I can do it” which is good but the market do not care about that. Whatever product you are making, it is very important to understand that it will be successful only if it solves a problem, launched timely to the market, easy to use, customers are happy with the experience, and quickly adapts to future requirements.

When starting a new project where RF connectivity is required like Bluetooth(BLE), WiFi, Zigbee, LoRa, etc. first critical question which comes to an engineer’s mind is whether to use a wireless SoC chip or a ready-made wireless module?

There are various factors which a design engineer or manager should consider before taking a decision in this direction, like time-to-market, in-house design expertise, compliance required as per country where you need to sell your product, expected size of the product, how production/production testing be handled, which method gives better flexibility, how you can make more future proof design or less effort required in future if need to migrate from one part to another. Of-course, it’s a trade-off. You need to decide based on your needs, which parameters are most critical and then judge which method is more suitable.

Below are my views on each of these parameters:

Time to market

Time to market plays a very crucial role in product’s success. If you are late you won’t get optimal margins or too many competitor products will be there. So from very starting, your decisions should keep your development time in control. Try to foresee all possible/potential issues that might occur going any route.

RF module greatly reduces time-to-market as you don’t need to worry about RF design but only the application part of it.

Design expertise

As you might already know, hardware is relatively difficult w.r.t software and RF is an extreme. You will need RF design expert engineers even though these days RF chip manufacturers are giving reference designs and good support. You need experienced engineers, who can understand the details, carry-out application layout, antenna design, debug the issues if comes during the development phase /field testing /production, that’s the most challenging part. You will also need expensive RF tools like test and measurement instruments with relevant software packages.

There are many companies (like Nordic, STMicroelectronics, Microchip, etc.) which are providing ready to use RF module connectivity solutions. If you go with an RF module, you just need to interface it with an MCU and everything else is already taken care by the module , like RF layout, Antenna (if module has PCB /chip antenna or SMA connector for external antenna). Design engineer can concentrate on the application development and its interfacing via SPI, UART, USB, SDIO, etc.

Compliance & Certification

Product need to be compliant to country’s norms. It looks easy but may pose serious delay if any deviation is detected w.r.t emissions. It may require multiple design and testing cycles which could be very expensive. Even if your design is compliant, you need it to be certified, which will add significant cost and effort.

These days modules are coming pre-certified, so you are saved from compliance testing hassles. Sure, you pay little extra cost but I think for low quantity (<50K approx. ) requirements, it make sense if we do detailed cost calculations. Cost & effort estimation should be done considering potential re-spin of the design and weeks/months of extra development time because of complexity involved and issues you might face. In RF design worst thing is, its difficult to quantify delays and cost these issues will take.

For the same reason, during new product development phase atleast, per my suggestion one should use module and get to the market fast.

Compactness / Size

Modules are obviously bigger than the chip itself but one need to carefully consider this parameter. Only if size is the biggest constraint then do a chip based design else in-general, in most of the cases module would be a good option.

Production (inventory, soldering, testing, etc.)

If you do a chip based design for whatever favorable reasons, you should consider how you are going to handle production (inventory, controlled impedance PCB, soldering, testing, etc.). In case any issue comes in any lot, whatever money saved in doing chip based design will go waste. Time & reputation loss in case design fails in the field is another thing.

I have seen companies facing issues in production due to lack of expertise, tools, etc.. They found it very difficult to identify the issues and lost many weeks & months debugging. Later had to take a decision to use the module. Even though they did initial successful chip based design, later they had to shift to module based design and were saved from all production/testing/debug hassles. Their manufacturing cost increased a bit but headache is far less. At the end, it comes down to what you want to achieve.

Flexibility

In case you need flexibility in your design like two different type of RF interface (BLE and WiFi), it becomes more complex when doing chip based design (now two), while module might give flexibility with ease. For example some modules have WiFi & Bluetooth both connectivity options.

Future proofing & time to migrate

Another important parameter to consider is, if in future, chip goes end of life (EOL), you need to do almost a full redesign and need to develop expertise on new chip. In case of a module, it’s not that difficult. Many designers keep a provision for two different modules using assembly options so that if one goes EOL, they have another compatible option on the same design.

Cost

It’s a pure quantity & application dependent. For example, in case of a medical product where quantities might be big, using a module is still ok as cost sensitivity is not high whereas for a high volume consumer grade product cost is a huge factor, so most of the times chip based approach is better.

Conclusion

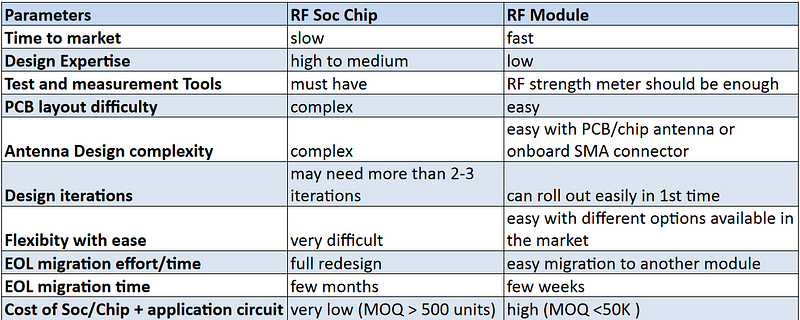

Here is a table which gives a quick comparison:

For low volume products, it makes overall sense to use module as you are saved from all the complexity involved by paying a little extra.

For a high volume consumer grade product you might need to consider starting with a chip-based design as there cost sensitivity is very high and may lead to failure due to higher product cost. But, their you will need in-house expertise & facility or outsource to other professional companies.

Some real life examples:

1.

Some of the phones where quantities will go in millions, uses ready wireless modules 🙂

2.

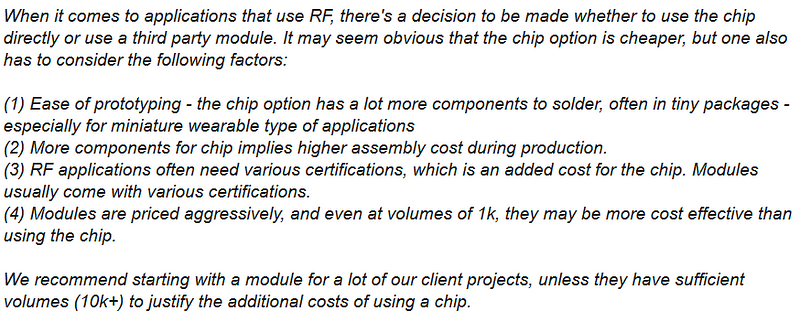

Below is the statement by Mahesh Venkitachalam, Founder of Electronut Labs, a Bangalore (India) based Startup providing consulting services in Embedded Systems design:

So, my suggestion is to take a decision considering all the relevant parameters and not just by mere cost of the chip or module.

Hope you are empowered to take better decision in your current or next Internet of Things (IoT) design.