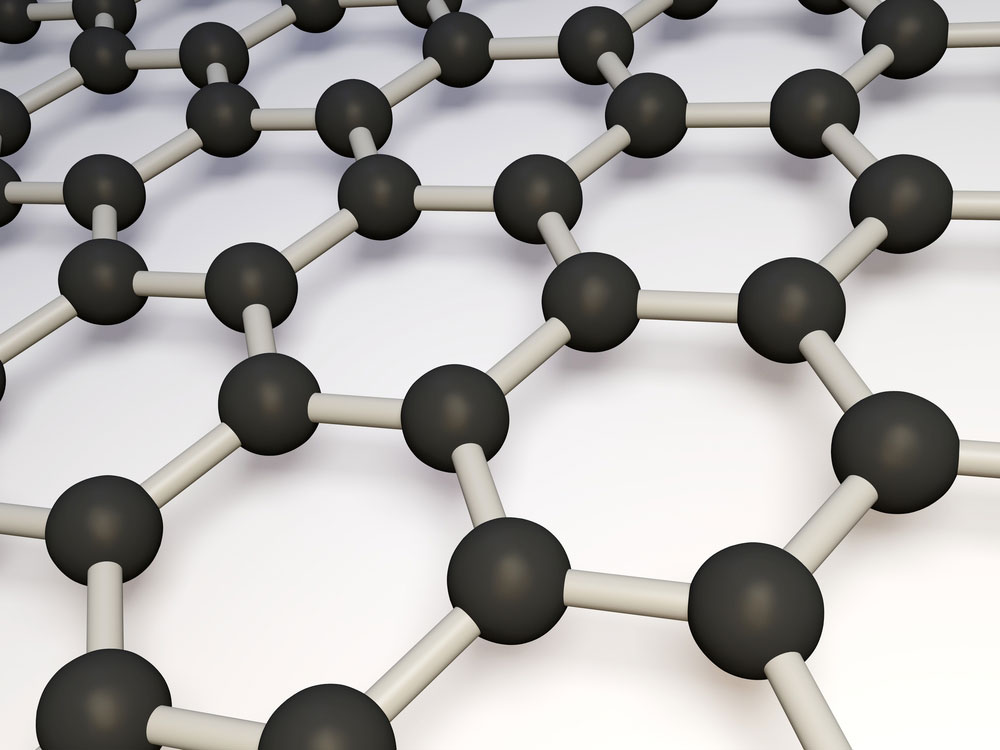

Oxford Instruments’ ALD and 2D specialists have teamed up with Eindhoven University of Technology (TU/e) to develop an atomic layer deposition (ALD) for 2D transition metal dichalcogenides for nanodevice applications.

The FlexAL-2D ALD system offers growth of 2D materials at CMOS compatible temperatures with precise digital thickness control over a large area (200mm wafers). Other features include self-limiting ALD growth for MoS2 and tunable morphology control over basal plane or edge plane orientation to create advanced 2D device structures.

According to the company, the wide parameter space offered by the FlexAL-2D ALD system allows growth of 2D transition-metal dichalcogenides at lower temperatures than employed in CVD furnaces.

First results on the growth of 2D MoS2 material by ALD at 450degC and lower temperatures were presented by Eindhoven researchers at the ALD conference in Denver this July. They showed how plasma-enhanced ALD was implemented to synthesize layers of 2D MoS2 films with tuneable morphologies (in-plane and vertically standing nano-scale architectures) on CMOS compatible SiO2/Si substrates. The 2D in-plane morphology has potential applications in nanoelectronics, while the 3D fin structures are ideal for catalysis applications such as water splitting.

Chris Hodson, ALD product manager at Oxford Instruments Plasma Technology is delighted with this research: “Dr. Bol and the Plasma & Materials Processing (PMP) group at TU/e are pushing the boundaries of ALD research into new application areas. 2D materials are a hot topic and utilising ALD to allow growth at lower temperatures and combine 2D materials with ALD deposition and other processing methods at 200 mm provide a new capability with many possibilities.”

The researchers are particularly interested in relatively low temperatures, says Ageeth Bol. “For CVD processes, typically temperatures of over a 800 degC are needed. That is often fatal for applications in semiconductors because the high temperature increases the diffusion of the atoms, which makes it harder to place them at the right spot. We want to have a process that yields materials of high quality at lower temperatures. This is especially important for the two-dimensional heterogeneous layers I am working on, since at lower temperatures less diffusion of atoms between the layers will occur.”