Every chemical substance absorbs a very individual fraction of infrared light. This absorption can be used with optical methods for identifying substances. Such methods are used in the chemical industry, for example, but also in the healthcare sector and in criminal investigation. If a company plans a new project, it often needs individually tailored sensor solutions. In the search for a suitable system, they are now supported by the EU-funded pilot line MIRPHAB (Mid InfraRed PHotonics devices fABrication for chemical sensing and spectroscopic applications) for the development of sensor technology and measurement technology in the mid-infrared. Three of Germany’s Fraunhofer institutes are participating in the project.

Lasting from the beginning of 2016 to the end of 2019, the MIRPHAB project comprises an 18-strong consortium funded by €13m from the European Commission’s Photonics Public Private Partnership (PPP) as well as €2m from the Swiss government. The aim is to create a reliable supply chain of mid-infrared photonic components so that companies (particularly SMEs already active in analytical MIR sensing) can make ready-for-use sensing devices by 2020. MIRPHAB is also establishing a pilot line to serve the growing needs of European industry in the field of analytical micro-sensors.

If a company is looking for a sensor solution, such as to identify a certain substance in the production process, it often has very individual requirements. This starts with the substances to be accounted for to the number of required sensors up to the speed of the production process. In most cases, a ‘one-size-fits-all’ solution is not sufficient, and several suppliers are needed in order to develop the optimal individual solution. In the MIRPHAB pilot line, leading European research institutes and companies from the MIR industry have joined forces to provide tailor-made devices from a single source. Interested parties can address a central contact person, who then compiles the best possible solution from the component portfolio of MIRPHAB members according to the modular principle.

To strengthen the European industry in the long term and expand its position in chemical analysis and sensor technology, the development of individual MIR sensor solutions within the framework of MIRPHAB is supported by EU funding. This significantly reduces the investment costs and hence the entry threshold for companies in the MIR sector. In combination with the virtual infrastructure developed in the course of MIRPHAB, high-quality MIR sensors are therefore also of interest to companies for whom the costs and development effort have previously been seen as being too high. In addition, MIRPHAB gives firms access to the latest technologies, enabling them to gain an edge over the competition as an early adopter.

Customized MIR laser source

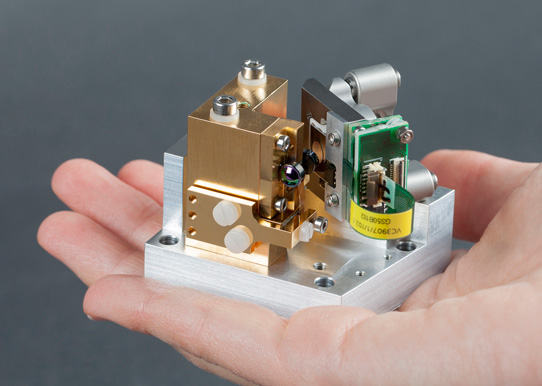

A central component of MIRPHAB sensor solutions is provided by the Fraunhofer Institute for Applied Solid State Physics IAF in Freiburg in cooperation with the Fraunhofer Institute for Photonic Microsystems IPMS in Dresden. Fraunhofer IAF is introducing the technology of quantum cascade lasers (QCLs), which emit light in the MIR range. In this type of laser, the wavelength range of emitted light is spectrally very broad and can be customized during manufacturing. To select a specific wavelength within the wide spectral range, it has to be chosen via an optical diffraction grating and coupled back into the laser chip. By rotating the grating, the wavelength can be tuned continuously. The grating is produced at the Fraunhofer IPMS in miniaturized form using micro-electro-mechanical system (MEMS) technology. This makes it possible to oscillate the grating at a frequency of up to 1kHz and to hence tune the wavelength of the laser source up to 1000 times per second over a very wide spectral range.

The Fraunhofer Institute for Production Technology IPT in Aachen is also involved in MIRPHAB in order to make the production of lasers and gratings more efficient and to optimize them for pilot series production. With its expertise, it transforms the production of the rapidly tunable MIR laser into industrially applicable production processes.

Process analysis in real time

At present, many applications in spectroscopy are still in the visible or near-infrared range and use relatively weak light sources. MIRPHAB offers solutions based on infrared semiconductor lasers. These have a significantly higher light intensity, enabling completely new applications. As a result, up to 1000 spectra per second can be recorded with the MIR laser source, which, for example, enables the automated monitoring and control of chemical reactions and biotechnological processes in real time. MIRPHAB says that it is therefore making a key contribution to the factory of the future and Industrie 4.0.