In-situ metrology system maker LayTec AG of Berlin, Germany has shipped two ILMetro in-line metrology stations to its customer CTIEC – part of China National Building Materials Group Corp (CNBM) – which has established a cadmium telluride (CdTe) thin-film photovoltaic (PV) production line in Chengdu based on technology developed by its German subsidiary CTIEC/CTF Solar.

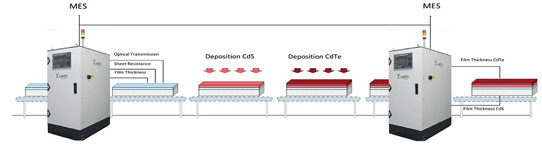

The two 24/7 ILMetro inline metrology stations are fully integrated into the fab’s manufacturing line and MES manufacturing execution system (see Figure).

ILMetro station #1 ensures 100% quality control of the incoming transparent conductive oxide (TCO)-coated solar glass substrates. It hosts a Suragus EddyCus in-line sheet-resistant unit and a LayTec Flames spectroscopic multi-head reflectance and transmittance system. Combining Eddy-current and spectral-optical methods provides full and automated statistical process control (SPC) of all key performance parameters of the TCO glass. The measured SPC data of station #1 are forwarded both to the fab’s MES system and to station #2.

ILMetro station #2 combines a LayTec Flames system (a multi-head optical metrology system for monitoring multi-layer thin-film structures in large area processes) with a LayTec SolR metrology system (an in-line, contactless, fast-probing white-light reflectance measurement system, capable of measuring the properties and thickness of all layers throughout thin-film solar cell manufacturing processes, including TCO and absorber and buffer layers). Multiple optical heads detect infrared (IR) and visible–near-infrared (vis–NIR) spectral reflectance from the front side and from the back side of the CdTe thin-film PV modules.

The resulting thickness uniformity of the CdTe absorber layers and of the very thin cadmium sulphide (CdS) buffer layers again are permanently reported with high accuracy to the fab’s MES system.

LayTec says that the ILMetro in-line metrology stations meet the IP54 and CE standards and are equipped with the necessary multiple interfaces for communication with the conveyor systems, third-party visual inspection systems as well as the fab’s MES and local-area network (LAN) automation system. Remote service and software maintenance is provided through a firewalled LAN.