- “Knocking” occurs on the premature self-ignition of the air-fuel mixture. Repeated knocking causes damage to the cylinder head gasket and cylinder head.

Hazards of Knocking-

- Loud noise (sharp knocking sound).

- Strong knocking reduces the power of the engine,

- The temperature of the engine rises sharply

- Overheating of the cylinder makes the metal soft, melt, or burn.

- The engine is unstable and vibrates violently.

SOLUTION is in DEFINITION

- The Knock sensor identifies the high-frequency engine vibrations (knocking) and transmits a signal to the ECU. The natural aim is to obtain a maximum energy yield by starting ignition as early as possible.

Place of Sensor-

- The knock sensor is mounted on the crankcase(mouth part of cylinder), the knocking is noticeable by its higher sound frequencies. This sound vibration are measured by a piezoelectric measuring element.

- Engines with a knock sensor can reduce fuel consumption and increase torque.

- Piezoelectric measuring element- It senses the variations in pressure-temperature or force and produces electric signals proportionally.

![]()

Features of Knock Sensor

- Characteristic curve-Linear over a broad frequency range.

- Temperature range−40 °C to +160 °C.

- Technology-piezoelectric measuring element (ring-shaped piezo ceramic).

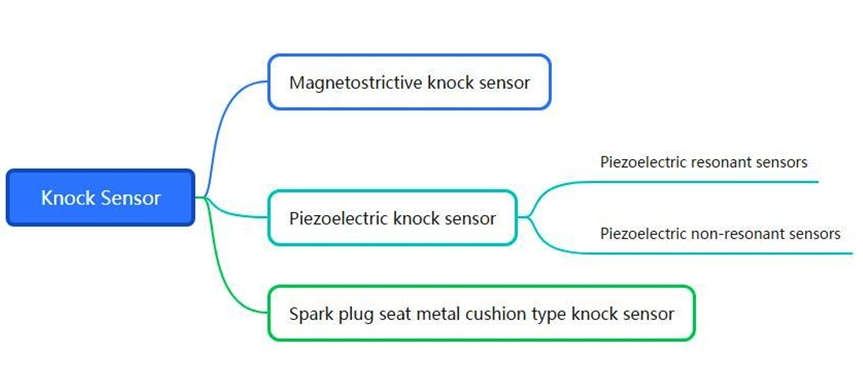

Types of Knock Sensor

- 1. Magnetostrictive Knock Sensor

- 2 Piezoelectric Knock Sensor

- 3 Spark plug knock Sensor

Applications of Knock Sensor

- Knock sensors are used in the car’s spark plug.

- Automotive industries.