Chargers using gallium nitride are starting to enter the market, capable of delivering high quantities of power to devices while staying a reasonable size, and even taking up less space than conventional chargers. AppleInsider explains what’s changed in chargers, and how it can help redefine the accessory industry.

What is Gallium Nitride?

Gallium nitride, also referred to as GaN, is a semiconductor that can be used to produce chips for electronics, in a similar manner to silicon. GaN is a transparent crystalline material, often used in the production of LEDs for the last 30 years, with its high frequency capabilities allowing for the production of violet laser diodes.

While silicon is the main material used for chip production, the limits of its properties relating to thermal and electrical transfer means it is getting harder for chip producers to work with it. As the race for smaller chip production processes intensifies, at some point the producers will have to look to other materials that could be used for processor creation in different ways.

GaN is the current best candidate to take over from Silicon, primarily for its “band gap” efficiency. The “band gap” refers to how a material can conduct electricity, with a wider band gap allowing for higher voltages to be used without issue.

What are its benefits over silicon?

In the case of GaN, its band gap is considerably higher than silicon, meaning it is capable of conducting far higher voltages over time. The bigger band gap also means that current is able to pass through a chip made form GaN faster than Silicon, which in turn could lead to even faster processing.

The band gap efficiency can manifest benefits in a number of other ways than processing speed. For example, as it is easier for energy to pass through, less power is needed to use a GaN-powered chip to offer similar benefits.

The efficiency also means the chips could be constructed smaller due to minimal energy loss, such as the case when a processor gets hot under load. This could mean more could be squeezed into the footprint of a silicon processor, or the footprint could be cut down in size, saving on material in its production and possibly physical size.

The higher voltage capacity also lends itself well to systems involving power transfers, such as chargers, while the ability to operate at higher temperatures could allow for components using it to be mounted in places where heat isn’t as much of an issue.

What does this have to do with chargers?

At their simplest, a charger applies a current to a battery in an attempt to reverse a chemical reaction inside each one. While early chargers applied a charge constantly without monitoring the battery itself, potentially leading to overcharging and damaging the battery, later versions include monitoring systems that can vary the current down over time, minimizing the possibility of overcharging.

Modern chargers as well as hardware which provides “power delivery” to other items, such as Thunderbolt docks or monitors providing power to a MacBook, sometimes provide considerable amounts of power to the device. For chargers with “fast charging” capabilities, this can give a battery in a smartphone half of its capacity in terms of available power in a short space of time, before reverting to lower current levels as it gets fuller.

For phone and device chargers, the use of the high-voltage GaN means more power can be transferred at a far higher efficiency than silicon, making them more suitable for this sort of application.

Since more power can be shifted through GaN components, which can also be made more compact than their silicon counterparts, this means that more can be built into the GaN component instead of relying on multiple silicon components, shrinking the amount of components required for a charger, and potentially allowing for the overall size of the charger to be smaller.

To consumers, they can expect GaN chargers to be smaller in stature than current-generation chargers, as well as some that keep the same size but offer the ability to provide power to more devices, as well as being able to charge high-Watt items like MacBooks with ease.

Why are we still using older charging technology?

In short, money.

The processes to create silicon components are already widely established and reasonably cheap on a per-component basis. GaN is still relatively in its infancy for commercialization, which makes it more expensive to produce than silicon, so until it becomes cost-effective with its benefits to create GaN components, firms lack much of an incentive to switch over.

For the moment, only a few semiconductor vendors are producing GaN components, and it won’t be until the major semiconductor fabricators start using the material at a high scale for chips that costs won’t reduce.

his means not many charger manufacturers are using GaN as could be, but this is likely to change once the supply and cost become more reasonable. Even so, several companies are taking advantage of the technology’s benefits now.

What GaN chargers are available right now?

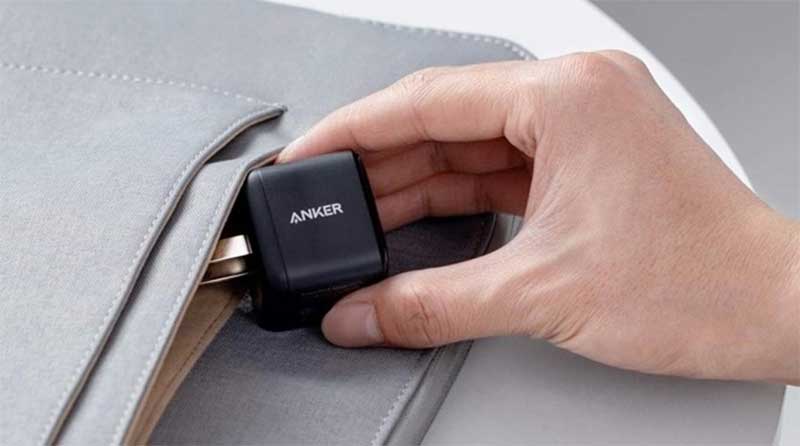

One major example of how small a GaN charger can get is the Anker PowerPort Atom PD 1. Measuring 1.6 inches by 1.8 inches by 1.5 inches, the compact cube is a 30W USB-C charger that is capable of charging larger devices as well as smaller items.