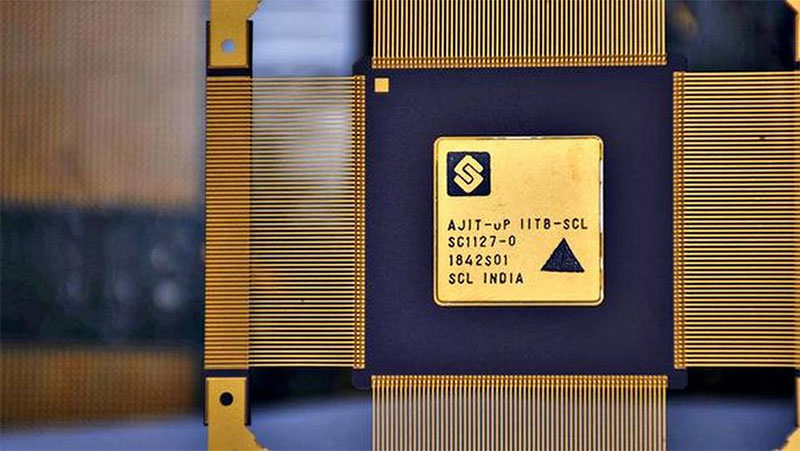

IIT-B researchers develop AJIT ‘Made in India’ microprocessor.

IIT-B researchers develop AJIT ‘Made in India’ microprocessor.

Engineers from the Indian Institute of Technology Bombay (IIT Bombay) have developed a microprocessor called AJIT, the first to be conceptualised, designed, developed and manufactured in India. The innovation, which has brought industry, academia and the government together, could reduce the country’s dependence on imports.

The project was funded by the Ministry of Electronics and Information Technology (MeitY) and IIT Bombay. Powai Labs, a Mumbai-based company, has invested in the venture, and will own, market and support the product.

Prof. Madhav Desai of the electrical engineering department and his team of nine researchers from IIT Bombay designed and developed the processor entirely at the institute. In a sense, the researchers have built the first proof of concept, Prof. Desai told The Hindu. “It is out of the laboratory, but not on the road yet. We are refining it. If successful, it will be mass produced.”

India’s electronics market is expected to reach $400 billion by 2020. Most of the electronic devices we use are imported; only a quarter of the devices are produced in the country.

An electronic equipment that is almost always imported is the microprocessor: the ‘brain’ of an electronic device. A microprocessor is an integrated circuit that contains a few million transistors (semiconductor-based electronic devices) fused on a semiconductor chip. It is just a few millimetres in dimension and is used in almost every electronic device, from the microwave and washing machine in homes to supercomputers of a space station. However, developing and manufacturing it is not easy; it is expensive, risky, and needs skill. Hence, only a handful of companies across the world have been able to manufacture and sell microprocessors.

If a microprocessor is home-grown, manufacturers of electronics devices could benefit from the ready availability and competitive price of an Indian device with an added advantage of having the design and support team nearby. “Geographical proximity could easily make it possible to get something done in say two weeks, instead of three months required otherwise,” Prof. Desai said.

Prof. Desai and his team developed a tool set called AHIR-V2, which can convert an algorithm to hardware to design the microprocessor circuit. AJIT (named after Prof. Desai’s friend and mentor who died in an accident a few years ago), is a medium-sized processor. It can be used inside a set top box, as a control panel for automation systems, in a traffic light controller or even robotic systems. What’s more, the researchers expect AJIT to cost as little as ₹100 when it is produced en masse.

Prof. Desai said he saw the microprocessor in use in embedded systems. “It’s not for mobile phones yet but not for trivial uses like washing machines either. We can do serious things with it, like use it in WiFi routers, secure power metres or even electronic voting machines.”

In the first stage, AJIT has been manufactured in the government-owned Semiconductor Laboratory, Chandigarh. It has a technology that offers the smallest building block of the size 180 nanometres (nm). The researchers plan to commercially manufacture the processor using more advanced techniques that provide the smallest building block of size 65 nm or 45 nm, which is state of the art. “Fabricating this using 180 nm technology is the first step. Although this may not be state-of-the-art technology, it is enough for most of the targeted applications. Using advanced technology for large manufacturing quantities — tens of lakhs — would bring the cost per piece down,” Prof. Desai said.The researchers have made the software tools associated with AJIT freely available. The processor is also available as a ‘softcore’, where vendors can buy a licence to use the design of the microprocessor and fabricate it to use it in their system. The researchers also offer to customise the processor for specific applications, and plan to introduce AJIT to academia. “A well-designed single-board computer system could be made available at a low cost for students and other enthusiasts to experiment with,” he said.

Building the indigenous microprocessor came with its set of challenges. Prof. Desai had only a small group graduate students who worked on a shoestring budget.

When the team started work in 2015, they were clear it would be a five-year effort. “The first year was about getting the first implementation, and building a prototype. And then validate the prototype and get it manufactured.”

There are tougher challenges ahead. “We need to get more people to use AJIT. If the business community would own this processor, build systems around it so that users, as well as supporters, see value in this and can make money from the effort, then this effort can remain sustainable,” Prof. Desai said.

Verification of the system, he said, was very complex. “It takes effort and ingenuity. It is up to us as a research and development organisation to take it to its proper culmination,” Prof. Desai said.

MeitY has extended its funding to enhance the processor and deploy it in government-initiated projects. SAMEER (Society for Applied Microwave Electronics Engineering & Research), an independent laboratory under MeitY, is planning to use AJIT in the receivers being developed for NAVIC or IRNNS (The Indian Regional Navigation Satellite System), an indigenous navigation system for the Indian subcontinent.