The ceramic trimmer capacities are constructed in two forms as under :

- Rotary type ceramic trimmer.

- Concentric type ceramic trimmer.

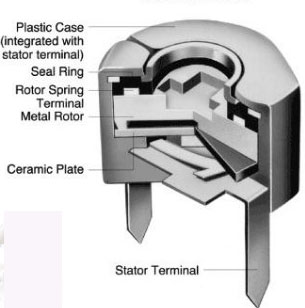

- The construction of rotary type ceramic trimmer capacitors is shown in above fig.

- The ceramic trimmer consist of two small flexible metal plates separates by a dielectric. It has three parts: rotor, stator and dielectric. The rotor carries a semi circular pattern.

- This pattern consists of metallization of rotor to provide an electrode. The rotor pattern is usually semi-circular to utilize maximum resolution capability during tuning.

- The top ratable semi-circular plate is made up of high permittivity material with suitably chosen temperature coefficient. The stator consists of silver plates to provide an electrode. The dielectric is usually titanate ceramic placed between rotor and stator.

- The base of this capacitor is made up of low loss and low permittivity steatite.

- The base of the pivot is riveted over a sparingly metal disc to form contact with the rotor and allow rotation.

- The bottom surface of a rotor plate and top surface of a stator plate are made flat to provide intimate contact between plates and to exclude air between two plates. It assures stability.

- The spacing between the plates can be changed by means of a screw adjustment. As the screw is rotated inwards, the plates are compressed and its capacitance value is increased.

- These capacitors are available up to 120 pF. In case of concentric type, a long metallic screw is running in a ceramic tube, which is silvered on outside.